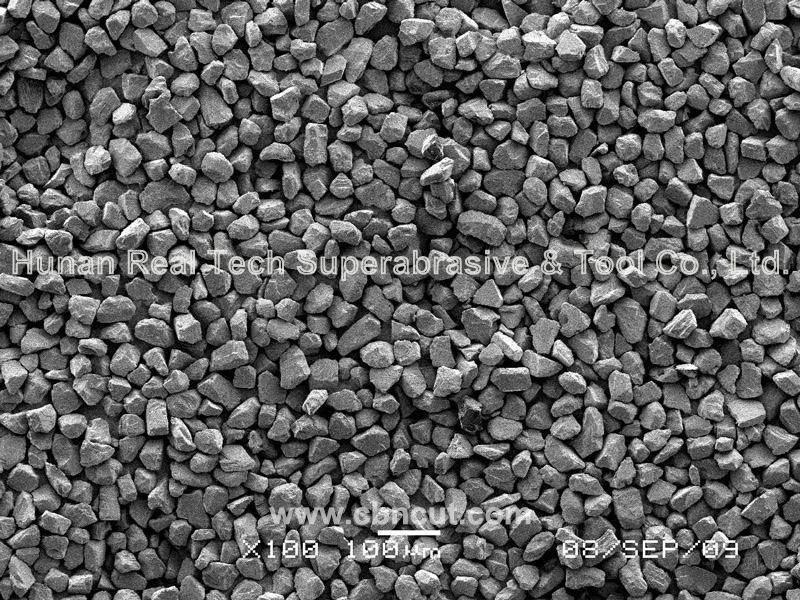

Diamond Micron Powder for Diamond Wire RMD

Characteristics: This grade of Diamond Micron Powder,Diamond Polishing Powder used for the diamond wire cutting tools, it is produced by specialized technique with premium grade MBD diamond raw materials,high strength,regular crystal shape, highly concentrated particle size distribution & effective particles, strictly control of rod-like and flaky shape particle, low impurity, high cutting efficiency of good sharpness, prominent dispersity and wear resistance.

Applications: Make diamond wire for dicing & slicing monocrystalline silicon, polycrystalline silicon, sapphire, LCD, magnetic materials, semiconductor materials, also used for other premium diamond grinding & polishing tools.

Available Coatings: The diamond micron powder can be Chemical Ni coating,Electroplated Ni coating,Ti-Ni composite coating,customized coatings are also available.

Nickel coating can greatly enhance the retention between diamond particles and core wire.

Diamond Micron Powder Particle Size Comparison Chart

| Chinese Standard (um) | Product Designation Size (um) | Factory Workshop Standard |

Equivalent US Mesh Size |

| 0-0.25 | 0-0.25 | W0.25 | 60000# |

| 0-0.5 | 0-0.4 | W0.5 | 28000# |

| 0-1 | 0-0.8 | W1 | 15000# |

| 0.5-1 | 0.4-0.8 | — | — |

| 0.5-1.5 | 0.4-1.2 | W1.5 | 13000# |

| 0-2 | 0-1.6 | W2.5 | — |

| 1.5-3 | 1.2-2.3 | W3.5 | 8000# |

| 2-4 | 1.6-3.1 | — | 5000# |

| 2.5-5 | 1.9-3.9 | W5 | 4000# |

| 3-6 | 2.3-4.7 | W7 | 3000# |

| 4-8 | 3.1-6.2 | — | 2500# |

| 5-10 | 3.9-7.8 | W10 | 2000# |

| 6-12 | 4.7-9.3 | — | 1500# |

| 8-12 | 6.2-9.3 | W14 | 1200# |

| 10-20 | 7.8-15.5 | W20 | 800# |

| 12-22 | 9.3-17.1 | — | 700# |

| 20-30 | 15.5-23.3 | — | 600# |

| 22-36 | 17.1-27.9 | W28 | — |

| 36-54 | 27.9-41.9 | W40 | 400# |

Related links of synthetic diamond grits and diamond powders as follows: